- Age and Weather Resistant Butyl Rubber Formula

- 100% Solids Content

- Meets AAMA Certification

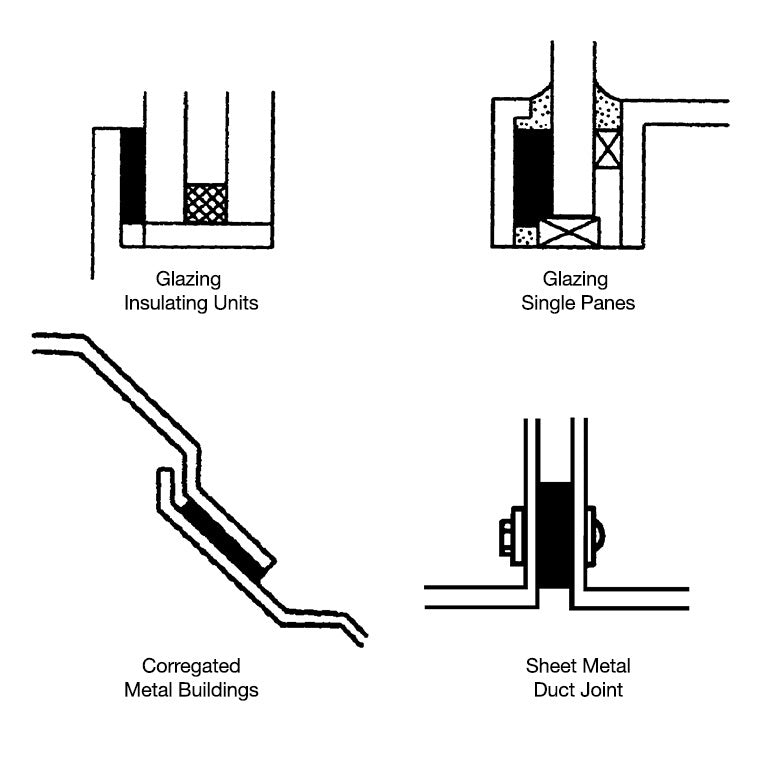

- Used as an Exterior Primary Spacing and Glazing Seal

- Available in Gray and Black

CRL Butyl Architectural Glazing Tape is an extruded, preformed tape furnished on release paper rolls. Based on a butyl rubber formulation with proven age and weather resistant properties, it is designed to create a long lasting, flexible weather seal between two surfaces that will be subjected to normal expansion/contraction and wind loading forces. It is used as an exterior primary spacing and glazing seal when glazing glass into a window sash; also used to seal other architectural surfaces such as metal to metal joints, wood to glass, metal to plastic, etc. The thickness is designed to be compressed approximately 10 percent at installation to accommodate surface alignments.

Typical Properties

Base Polymer: butyl rubber (polyisobutylene); Solids Content: 100% solids (no asbestos); Cure Time: fully cured before application; Hardness: 20 durometer Shore "A" @ 77° (25°C); Temperature Range: Application 20°F (-7°C) to 120°F (49°C); Service -40°F (-40°C) to 190°F (88°C); VOC Content: 0%; Joint Movement: ±15% of joint width; Service Life: 20 year minimum.

Limitations

For applications above two floors use a spacer, shim, or a structural cap bead (such as silicone) to prevent over compression or use CRL 100+ Load Bearing Glazing Tape.

Applicable Standards

AAMA 804.3, 806.3, and 807.3. ASTM C1281

Good Glazing Practices

The following "Good Glazing Practices" are recommended when using CRL Glazing Tapes. Surfaces to be adhered should be free of frost or standing water, brushed clean, solvent washed (MEK, Toluene or Naptha) and wiped dry. At installation, positive contact and approximately 10 percent compression is recommended to fully marry surfaces to be joined. Glazing tapes kept under compression with clips or wedges provide the best seals.

Always use setting blocks (80 durometer Shore "A" hardness) placed at the sill quarter points. Spacing shims are recommended to accommodate wind loading when glass lite is over 100" (50 durometer Shore "A" hardness). Tape placement on the sill rabbet is not to be below the sight line unless a cap bead is specified, then tape is placed 3/16" (4.8 mm) below the sight line to allow for the cap bead. Do not overlap tape to join; always butt ends without stretching. To keep the tape surface clean, leave the release paper in place until ready-to-set the glass.

Product Warning:Limitations: For applications above two floors use a spacer, shim, or a structural cap bead (such as silicone) to prevent over compression or use CRL 100+ Load Bearing Glazing Tape.

Product images shown are of the actual product or a close representation. Colors can vary depending on your computer's video card and on how your monitor's color is adjusted.