- Ideal for Sheet Metal Fabricators and Solar Energy Panel Installers

- Available in Sizes 78" to 168" (2 to 4.4 m)

- Unparalleled Bending Power

- Incorporates the Latest Technology

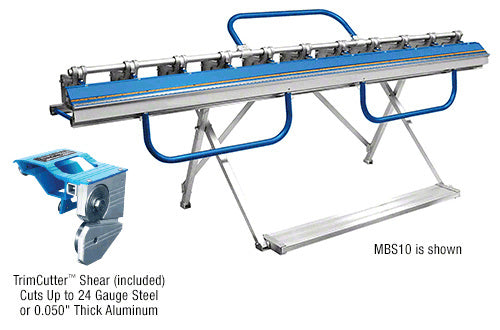

CRL's Metal Brake and Shear is designed for single user set-up and operation in the shop or on the job site. It will bend residential grade metals and most commercial metals used in roofing, siding, window, and gutter installations. The 14" (356 mm) throat allows for complex bending profiles and features a unique cam-locking system, along with new POWERslot™ technology for improved bending leverage. The stainless steel strip protects the bending edge and provides a superior guide for scoring material.

NOTE: Capacities are based on standard metal properties for coil & sheet. Please contact CRL for capacities on your specific material.

For cutting or shearing metal simply position your metal sheet into the brake and lock in place. Place the separate TrimCutter® (included) onto the upper right side of the brake. Roll the TrimCutter® along its track shearing the metal to size. The TrimCutter® will cut painted steel sheet up to 24 gauge thick or .050 thick aluminum. A non-marring vinyl strip protects metal finishes, including clad, while leaving clean crisp bending lines and hems every time.

Each unit comes with a patented Xtreme™ shop stand that does not shake, rattle or loosen under any work load or job situation. With the longest service life of any portable brake of this class, you can depend on getting many years of reliable service.

CRL also has other Brakes and Shears available with different throat capacities, material thickness adjustments, and sizes which offer both shop and job site functions and features. For additional information contact CRL Glass and Glazing Technical Sales.

MATERIAL CAPACITIES:

Aluminum: Alloy 3003H14

Max: .050

Galvanized Steel:

Max. 20 Gauge

Painted Steel: Grade D

Max: 24 Gauge

Roofing Copper:

Max. 36oz Soft

Zinc:

Max. .050 Soft

Stainless Steel: Alloy 304L

Max: 24 Gauge

Product Warning:

All Metal Brake and Shear machines are packaged in a heavy corrugated box for shipping.

Product images shown are of the actual product or a close representation. Colors can vary depending on your computer's video card and on how your monitor's color is adjusted.